The latest report titled “Analysis of Nicotine Sulfate Production” by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of Nicotine Sulfate.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/nicotine-sulfate/request-sample

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Nicotine Sulfate production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Procurement Resource Assessment of Nicotine Sulfate Production Process:

- From Acidification Reaction: This report presents the detailed production methodology and cost analysis of Nicotine Sulfate industrial production across Nicotine Sulfate manufacturing plants. The production process starts by extracting nicotine from tobacco leaves through solvent extraction. Tobacco leaves are treated with solvents such as petroleum ether or methanol to extract nicotine for subsequent reactions. The extracted nicotine is then mixed with kerosene and transferred to a reactor for acidification with dilute sulfuric acid. This reaction between nicotine and sulfuric acid yields nicotine sulfate as the final product.

Request For Free Sample: https://www.procurementresource.com/cost-analysis/nicotine-sulfate-production-by-acidification-reaction/requestsample

Product Definition:

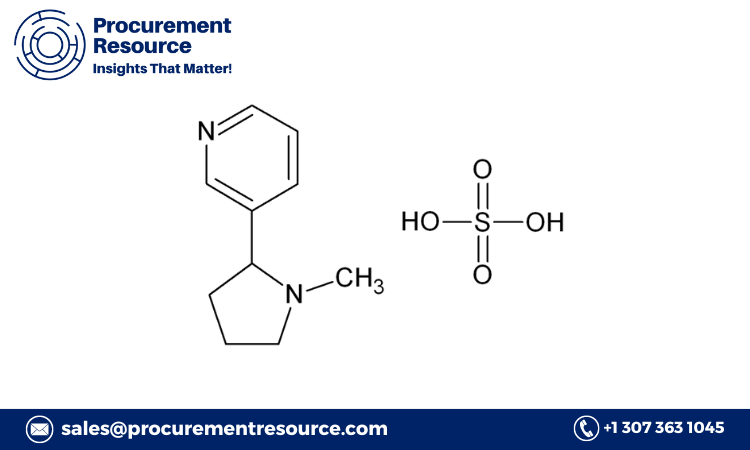

Nicotine sulfate is a colorless to white crystalline compound with a complex chemical structure containing twenty carbon, thirty hydrogen, four nitrogen, four oxygen, and one sulfur atom. With a chemical formula of C20H30N4O4S and a molecular weight of 422.5 g/mol, it is a crystalline solid that melts under heat and is moderately soluble in water, as well as in solvents like alcohols and ether. Its density is 1.15 g/cm3 at 25°C. When heated, nicotine sulfate decomposes, releasing toxic fumes of nitrogen oxides. Derived from tobacco leaves, it is produced by reacting nicotine from tobacco with sulfuric acid. Nicotine sulfate is a non-combustible salt with toxic properties. It can react violently with strong oxidants and is explosive under fire conditions. Primarily used in agrochemical and pharmaceutical applications, nicotine sulfate’s toxicity makes it valuable in producing insecticides for agricultural use. It effectively eliminates various pests such as worms, bugs, aphids, and leafhoppers. The compound is widely employed to protect fruits and vegetables from insect damage. Additionally, nicotine sulfate is used in the production of fumigants and pharmaceuticals for animals.

Market Drivers:

Nicotine sulfate is a chemical compound primarily used in pesticides, especially in agricultural settings. Its market drivers are influenced by various factors related to its applications, regulations, and market dynamics. Here are some key drivers:

- Agricultural Demand: The primary use of nicotine sulfate is as an insecticide in agriculture. The demand is directly linked to the need for pest control in crop production. Factors such as crop yield targets, types of crops grown, and the intensity of pest infestations significantly impact the demand for nicotine sulfate.

- Regulatory Environment: Regulatory policies play a crucial role in shaping the market. In some regions, there might be stringent regulations limiting the use of nicotine-based pesticides due to their toxicity and environmental impact, which can restrain market growth. Conversely, in regions with less stringent regulations, the market might experience growth.

- Alternatives and Substitutes: The availability of alternative pesticides, such as those based on newer, less toxic, or more effective chemicals, can reduce the demand for nicotine sulfate. The development of genetically modified crops that are pest-resistant also decreases dependence on chemical pesticides.

- Environmental and Health Concerns: Increasing awareness and concern about the environmental and health impacts of pesticides can influence market dynamics. There is a growing preference for organic farming and natural pest control methods, which may limit the use of chemical insecticides like nicotine sulfate.

- Economic Factors: The overall economic condition of the agricultural sector, including investment in crop protection and the cost-effectiveness of various pesticide options, also influences the market for nicotine sulfate. Economic downturns or reductions in agricultural spending can lead to decreased demand.

- Research and Development: Innovations in pesticide formulations and the development of more effective or environmentally friendly alternatives can impact the market. Investment in R&D to improve the efficacy or reduce the negative impacts of nicotine sulfate could drive its market.

Understanding these drivers is crucial for stakeholders in the agricultural chemicals industry to navigate the market effectively and make informed decisions.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

- Adapting the report to the country/region where you intend to establish your plant.

- Adjusting the manufacturing capacity of the plant according to your needs.

- Customizing machinery suppliers and costs to meet your requirements.

- Providing additional information to the existing scope based on your needs.

About Us:

At Procurement Resource, we empower our clients to stay ahead in their industries through strategic procurement intelligence. Our seasoned team of analysts, researchers, and domain experts conducts rigorous research to deliver the most current market reports, cost models, price analyses, and category insights. These tools are designed to streamline the procurement process, enhancing efficiency and decision-making. We collaborate closely with a variety of procurement teams across different sectors, gathering real-time data and insights that are immediately applicable. By monitoring a wide array of goods and commodities for the latest prices and production costs, we provide dependable, up-to-date information. Our use of advanced industry techniques also enables clients to gain a deeper understanding of the supply chain, procurement dynamics, and the broader industry environment, thereby aiding them in developing strategies for sustained growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA